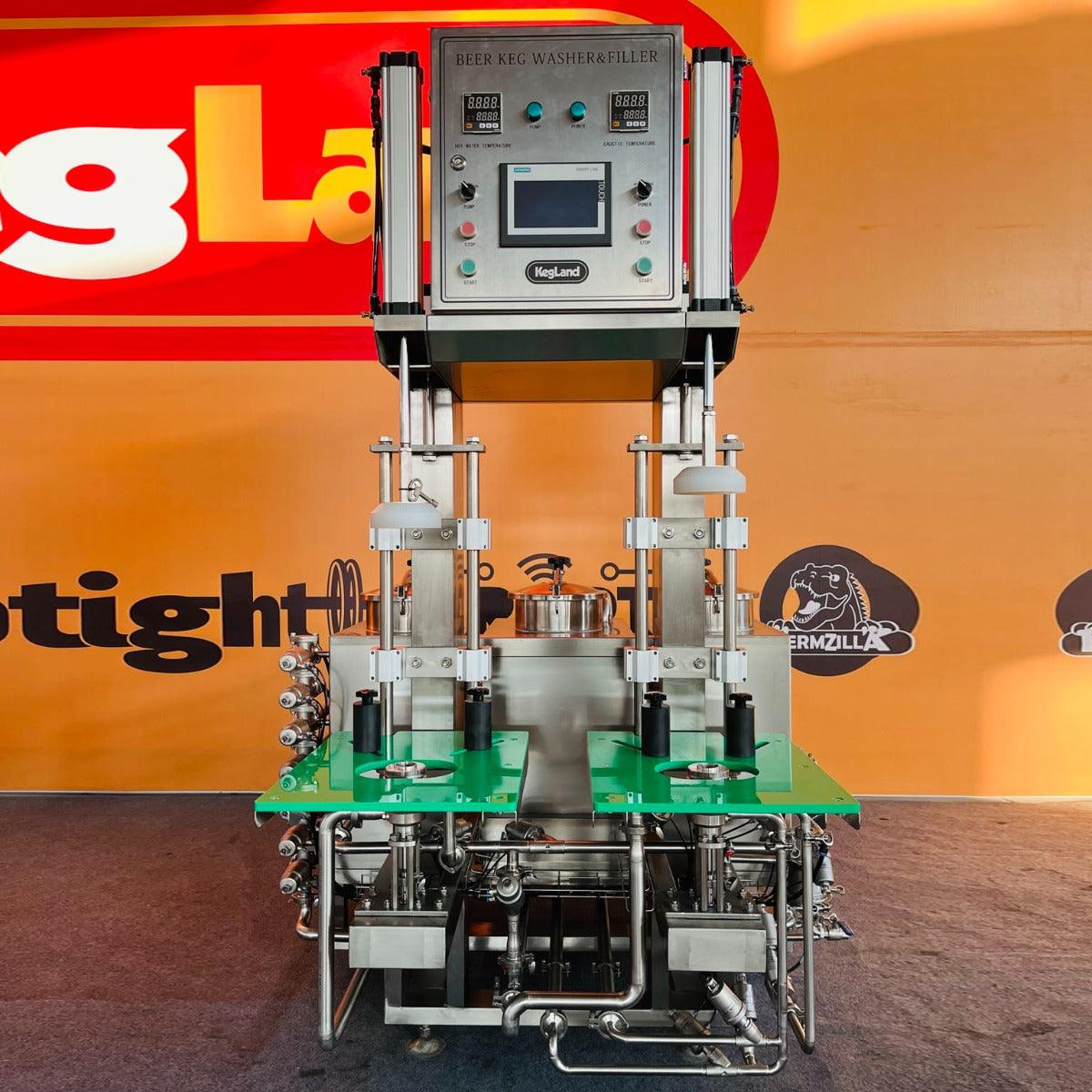

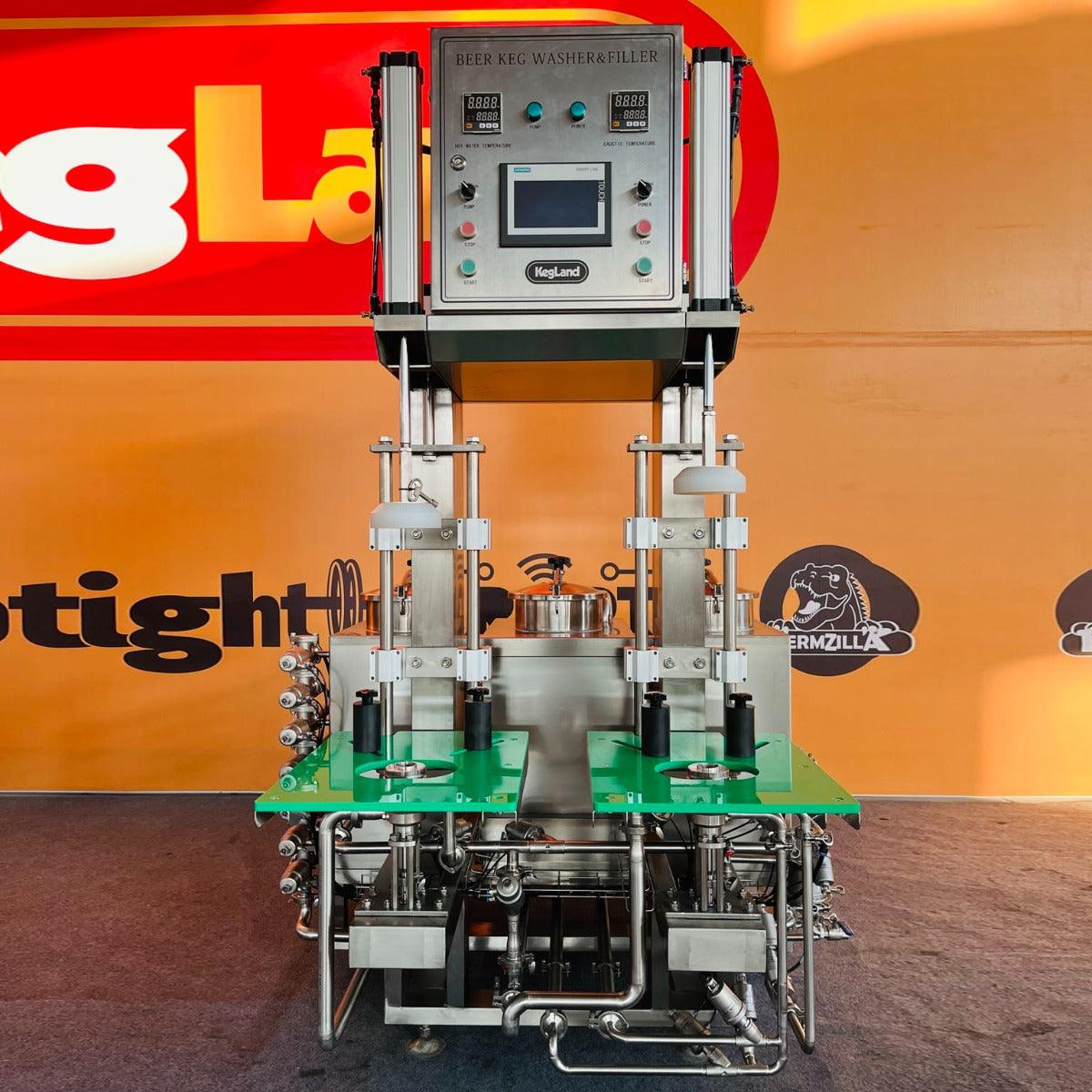

Keg Washing & Filling Machine

Description

This fully automated keg filler and washer is designed for commercial use for any serious brewery that needs consistent high quality packaged beer results. This machine is reliable, easy to operate, fully customizable, and will ensure the quality of your beer is preserved throughout the process.

If you have a commercial brewery and need a fast and efficient keg washer you have come to the right place. KegLand now manufactures this Siemens S7-200 PLC controlled keg washing, sanitiser and filler that will greatly reduce labor cost, improve the DO for your keg fills and also ensure you hare efficiently filling kegs as fast as possible.

- The Washing and Sanitising Process

a. Once you place the keg onto the table the pneumatic pressure will automatically couple with the head of the keg.

b. The keg is first emptied of residual beer.

c. Water is rinsed into the keg

d. Water is then cleared from the keg using air or CO2 to blow the residual water from the keg(this water rinse process is to reduce contamination to your custic tank and enables you recirculate caustic for a significantly longer time before needing to change)

e. Caustic is then used to wash the keg

f. Hot water is rinsed into the keg to remove residual caustic

g. Sanitiser is then used to sanitise the keg (normally phosphoric or some other acid wash)

h. Water is then rinsed into the keg again

i. If you have steam boiler available then this is where you can program a steam sterilization

j. You can program a further water wash here

k. CO2 Purge (If you have steam connected you may be able to omit the CO2 purge but you will need to test your DO to confirm this)

l. CO2 pressurise (so the keg is ready to fill)

NOTE: All steps in the above process are programmable via the touch screen PLC controller allowing you to omit certain steps or increase or decrease the parameters. - Filling Process

a. CO2 is pressurised into the keg (to ensure you have some counter pressure in the keg)

b. CO2 is blown into the spear to clear out residual drips from the cleaning/washing process

c. The filling process begins

d. Filling process stops

e. CO2 is used to clear the filling head

f. Unload the keg from the machine

Reduced Risk and Improved Quality

One of the major reasons to use an automated process that cleans, sanitises and prepares the keg for filling is to reduce the chance of mistakes. Manual keg washers and fillers will always have some variability meaning your staff might not quite fill every keg to the same level or sufficiently purge the keg or even worse, the may not rinse caustic out of the keg before filling. This PLC controlled automation will ensure once you have your desired settings saved in the PLC the process will be robust and unlikely to fail. It also ensures your packaged kegs are done to a level of consistency that you would expect from a commercially opperated brewery.

Couplings Included

This machine includes both A-type and D-type coupling heads (which covers you for 90% of kegs in Australia).

Tri-Clover Fittings

The plumbing for this brewery is designed so it can easily be taken apart using standard brewery tri-clover fittings.

Low DO

When purchasing any hardware for packaging beer "how much dissolved oxygen (DO) ingress will I get" should be one of the first questions you ask. This machine when used at the stated 30-40 kegs per hour will enable you to achieve DO levels of 50ppb or less. If however you are prepared to purge a bit longer, consume a little more CO2 and reduce your cycling speed then you can get well under this number.

Steam Possible

This particular keg washer, cleaner and filler is fitted with a hot wash and sanitising tanks. If however you have a stem boiler at your brewery you can also divert the steam into this unit and bypass the sanitising tank and use steam instead.

Specifications:

Power Draw: 3KW

Capability: 30-40 kegs per hour

Compatible Keg Sizes: 5L - 60L

Air Pressure: 5-6 Bar

Beer Supply Pressure: 1.5-2.5bar

CO2 Pressure: 2-3bar

Air Blow Pressure: 3bar

Shipping

Shipping prices are calculated on the checkout page based on the size, weight, and where it needs to be delivered. You can be confident that you will receive accurate and fair shipping rates specifically tailored to suit your individual purchase.

Once an order is placed, please note that KegLand is unable to make changes or additions to the order or modify the shipping information. If any changes are required, it is the customer's responsibility to directly contact the shipping provider and arrange for redirection or any necessary adjustments.

Read More: Shipping Policy

Product Downloads

Suggested Videos

This product has no reviews yet.

This product has no reviews yet.

This product has no reviews yet.